Air doesn’t belong to anyone, yet it travels through all of us. One factory’s chimney may sit on the edge of an industrial district, but the air it touches doesn’t stay there. Wind carries it to nearby towns, schools, fields, oceans, and eventually, into our lungs. That’s why more factories are being pushed. Not by inspiration or moral lessons, but by regulations, community pressure, and health concerns, to clean the air they release.

This is where air pollution control systems come in. They don’t erase the impact of industrial production, but they help make the air that leaves smokestacks far less harmful than it would be otherwise.

What Happens to Polluted Air Inside a Factory?

When raw materials are heated, cut, melted, or chemically processed, they release gases, vapors, and tiny particles. Metalwork, chemical plants, fertilizer production, dye manufacturing, paper mills, each process leaves something behind in the air.

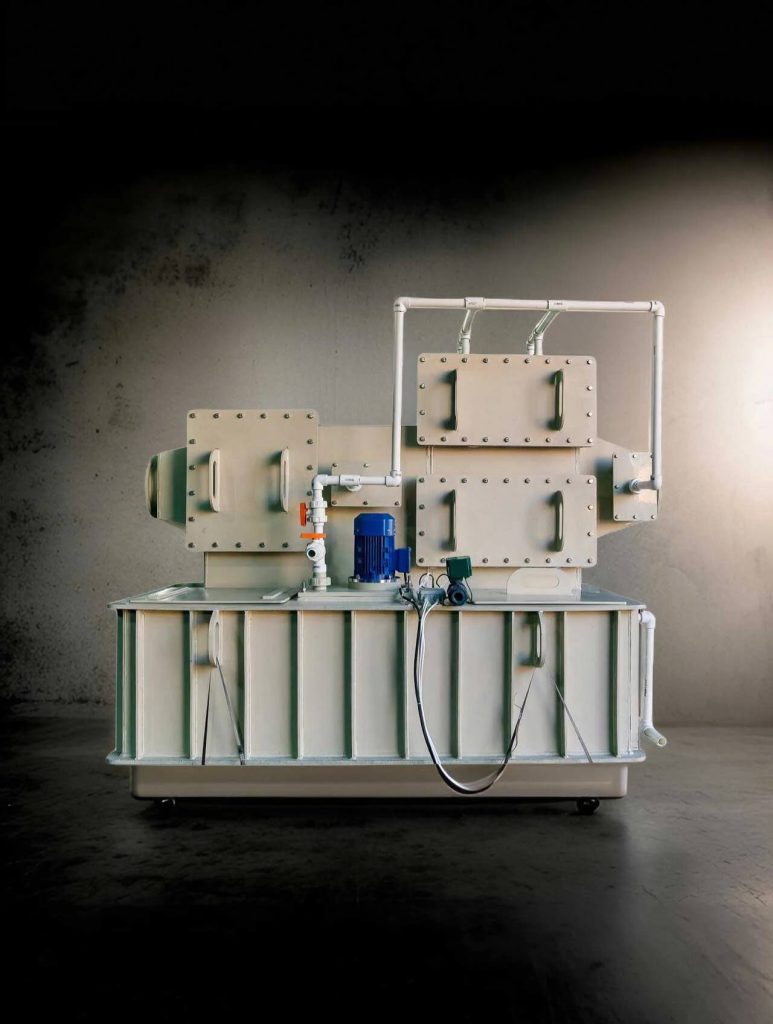

Instead of releasing polluted air straight into the atmosphere, many industries first send it through air-cleaning systems. One of the most widely used methods for gas-based pollution control is the wet scrubber, and its performance largely depends on the type of wet scrubber packing installed inside the unit.

Why Packing Media Matters More Than It Seems

Inside a wet scrubber, there’s usually a packed bed structure filled with wet scrubber packing. This material increases the surface area where air and liquid interact, allowing pollutants to transfer from the gas stream into the liquid more efficiently.

The choice of packing material directly affects how efficiently the scrubber operates. The most frequently used materials are:

- Polypropylene (PP): lightweight, corrosion-resistant, and suited to acidic environments.

- Ceramic: strong, heat-resistant, often used in high-temperature settings.

- Metal: effective but may corrode over time, especially in harsh chemical conditions.

Choosing the wrong material leads to blockages, reduced absorption, or early system failure. Choosing the right one keeps the scrubber working reliably for years. That’s why many producers focus on advanced designs and durable material blends rather than sticking to outdated solutions.

Where Does the Pollution Go?

Wet scrubbers don’t make pollution disappear. They simply move it from air to liquid.

Once the liquid absorbs pollutants, it becomes wastewater or sludge. This byproduct is then sent to treatment facilities, where it undergoes neutralization, pH balancing, and filtration before disposal or reuse. If a factory ignores this step, it risks contaminating rivers, soil, or groundwater. In other words, responsible air treatment must also include responsible water treatment.

Cleaner Air Doesn’t Mean a Clean Industry

Air purification systems don’t turn factories into environmentally harmless spaces. They reduce the damage. They lower corrosion in surrounding buildings, lessen respiratory problems in nearby communities, and help industries meet air quality standards.

But they don’t erase emissions entirely. They don’t fix climate change, nor do they solve overproduction, waste, or resource depletion. What they do, however, is minimize the harm done every second a factory is running.

A chimney releases air into the atmosphere, and wet scrubbers act as a filtration stage before that happens, removing as many pollutants as possible before the air is released.

Air Pollution Doesn’t Stay in One Place

In cities that border industrial areas, air quality varies not just with weather, but with how responsible nearby factories are. Poor air leads to an increase in asthma cases, skin irritation, fatigue, and long-term problems like heart disease. When factories use scrubbers and filtration systems, pollution levels drop, not completely, but noticeably.

Global regulations now reflect this. Many countries require industries to install systems like scrubbers, fabric filters, or electrostatic precipitators depending on what they produce. Failure to do so can result in heavy fines or shutdowns.

What the Future of Industrial Air Might Look Like

The future doesn’t lie in removing all industry. It lies in quieter, cleaner, more responsible versions of what already exists. Factories will still produce glass, dyes, fertilizers, metal components. But how they handle the byproducts of those processes is changing.

Newer wet scrubber models use smarter nozzles, improved airflow design, and advanced packing materials.

Some even recycle treated water back into the system, reducing waste. Others integrate digital monitoring, so operators know when absorption efficiency drops and maintenance is needed.

A Shared Atmosphere

Someone can live beside a factory or far away in a quiet neighborhood, yet they still breathe from the same atmosphere. Air moves freely. It carries everything with it: smoke, salt from the sea, pollen from trees, fumes from metalwork, and steam from wet scrubbers.

Industries that treat their emissions before releasing them aren’t solving the whole problem. But they are recognizing that the air doesn’t just rise and disappear. It comes back to all of us in one form or another.